Infrared Applications

Benefits of Thermography

- Reduce facility downtime by predicting and repairing issues before they cause service interruptions

- Assess priorities for corrective actions

- Comply with insurance requirements

- Identify energy loss and water penetration in building envelopes

Roofing

Infrared testing is used to detect water damage and active leaks beneath the roof surface, allowing the opportunity to repair the leak before it can spread further.

Thanks to our partnership with United Infrared, we can also offer aerial thermography more affordably than ever before. This is great for those hard-to-reach roofs.

Building Diagnostics

Infrared testing is used to detect heating and cooling loss or moisture problems due to insulation deficiencies or construction issues. This can lead to huge energy savings in your facility.

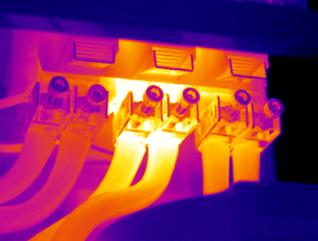

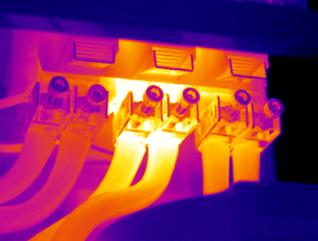

Electrical

Annual infrared surveys of your electrical equipment can save lives, production costs and downtime. Switchgear testing is the most popular application of infrared testing technology because it's non-disruptive (no shut down required), non-destructive and it works.

Mechanical

Motors can be monitored to allow downtime to be scheduled, allowing a plant to be pro-active insead of reacting to problems after they happen.

Bearings on drive shafts and conveyor systems can give good indicators of impending failure, allowing for replacement on your schedule instead of shutting down operations during peak production periods.

Blockwall/CMU

Distructive CMU blockwall testing can only show a very small sample size and X-ray is a very expensive technology. Infrared provides a much more thorough and affordable option to provide quality control to new CMU construction.